|

|

|

Our Tech Examples Applications FAQ Index Sales

|

What is ... |

|

Color, multispectral and other images can be a rich redundant source of identification information for many image interpretation applications. These include inspection and control of processes, robots and autonomous vehicles. Unfortunately, many engineers, seeking to automate such operations, have found that most commercially available software provides easy, robust, identification for only the simplest situations. Based on this, they take for granted that increasing complexity of colors, boundaries etc. must inevitably lead to corresponding increases in time and resources necessary for application success. Nothing could be further from the truth.

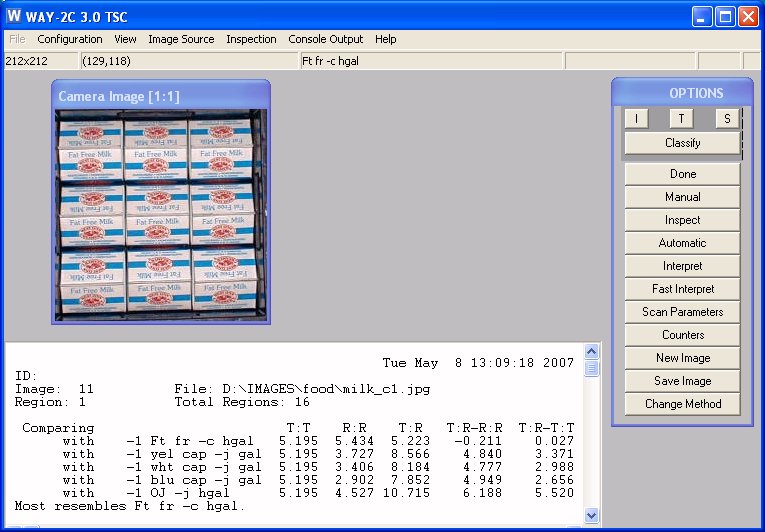

Using powerful statistical machine learning methods, WAY-2C software provides

easy to use classification, verification, and anomaly detection tools,

as applicable to complex textured and/or multicolored fabrics and natural scenes

as they are to the simplest single colored object.

WAY-2C's natural train-by-show method works equally well whether images come

from video or still cameras, thermal imagers, multispectral or even hyperspectral sources.

WAY-2C is operator trainable in a matter of minutes to recognize many objects on the basis of their color or similar distributions. Under script control training time may take only a few milliseconds. Logging and scripting capabilities facilitate complete or partial system automation. It can be controlled via external ports, over the net, or by user software. Output can be displayed on monitors and/or directed to output ports, the network, or other applications.

WAY-2C's interpretation and measure features permit determination of the amount of each class in the entire image or in selected regions. If desired a new color coded image can be generated to indicate the best fitting class at each point.

WAY-2C's verify and search features make it possible to determine whether members of a target class are present in part or all of an image or conversely whether items which are not members of that class are present.

Blob analysis can provide coordinates of identified areas of interest for robot guidance.

Applications include:

|

|

Whether classification or verification is involved, many of WAY-2C's applications fall naturally into one or more of the following categories: sorting/grading/labelling; process monitoring/control; assembly inspection; image interpretation. For most of these categories demonstration software and application notes are available which can form the basis for implementing your own specific applications using your existing product databases. Or, if you'd prefer we can provide you with a complete turn-key system.

Sorting, grading and labelling applications are usually concerned with determining which of several classes a single object belongs to and then performing some action on the object depending on its class. Typical applications include fruit and vegetable sorting, natural materials matching and grading, and plastic recycling.

Assembly inspection is primarily concerned with verifying that components are present and correctly placed. Examples include inspection of electronic and mechanical assemblies, pharmaceutical packaging kits and sample books. Timely assembly inspection may allow early corrective action and/or elimination of further resource waste on already misassembled items.

Other less obvious applications include complex label verification for contract bottling, and automated labeling based on size, color and/or which components are present, and verifying the presence of elements in a scene for security applications.

Process monitoring/control typically involves watching the output of a process and then optionally using the results to automatically modify the process to attain an optimum result. Typical examples include monitoring baking and roasting of foods, particularly those with inherently non-uniform or complex color distributions such as breads, meat, nuts, pies. One unusual use of WAY-2C is to analyze thermal infrared images to determine the height of molten glass in a high level nuclear waste vitrification project. Other applications include monitoring optical coatings and controlling product routing based on appearance.

Image interpretation is typically concerned with determining the relative amounts of various classes in a scene or parts of a scene. Typical examples include determining vegetation classes in a satellite image, amount of barnacles on a ship's hull, visible fat or lean in meat, locating ripe fruit on a tree or vine, a target in a field, stains in a microscope slide, or the exposed chips in a cookie.