|

|

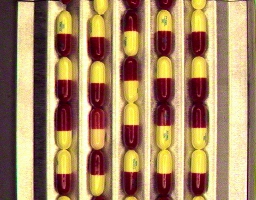

The upper image illustrates many problems characteristic of real-world color-based product inspection.

In this case the objective is to recognize anomalous product so it can be rejected. Such recognition is complicated by a number of factors including:

Both good and bad product show:

- multiple colors

- glints

- shadows

- unpredictable printing presence and position

- random orientation

- poorly predictable position

Depending on viewing angle, the lanes in the background show:

- color ranging from very dark to very light

- some reflections of the product color

Not surprisingly, users of traditional color analysis approaches have found that, even with single colored product,

while continuously scanning, averaging the color can result in erroneous color calculation and therefore inspection results (whether using RGB and/or HSI values).

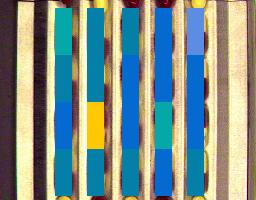

In spite of the complicating factors, using only a single simple training on good product,

WAY-2C is able to correctly differentiate between good (indicated by blues and greens) and anomalous

(indicated by yellow) product and generate a fail signal for the latter.

For "manual" training, testing and inspection demonstration see video. In normal production

applications the training is completely automated to quickly address situations such as lighting or camera drift or replacement. Automated training typically takes less than a second.

|